How Wood Flooring is Made – From Forest to Lumber

By Bruce Flooring Expert, Published August 21, 2025

Hardwood flooring has been a staple in homes for centuries, offering a natural, durable, and aesthetically pleasing foundation. However, creating the flooring you enjoy in your home takes time and numerous steps. The steps to transform raw lumber into elegant planks gracing your homes are part art and part science.

Here’s a look at that journey from forest to floor.

Hardwood Manufacturing: From Forest to Lumber

The next time you marvel at an old oak tree, understand that’s where the manufacturing process begins. According to scientists, some 230 billion trees cover forests in the U.S. The forestry community adds to that number yearly. Forest and conservation nurseries in the U.S. distribute about 1.3 billion seedlings annually, resulting in around 2.2 million acres of tree planting each year. The first step in the process is harvesting those trees. Red and white oak are the most commonly harvested species for hardwood manufacturing. They are abundant, which makes them more affordable.

Other common species include maple, ash, cherry, and hickory.

The Appalachian Mountains are a Prime Resource

The Appalachian Mountains are a primary source of hardwood for much of the wood products made in the USA. They have an abundance of the most popular hardwood varieties. Their trees produce solid wood flooring with clear grains, consistent colors, and excellent stability.

Bruce®, for example, has manufacturing facilities in the area, including those in Beverly, WV, and West Plains, MO. Bruce is the nation’s leading manufacturer of North American hardwood flooring.

Harvesting the Hardwood for Manufacture

If we focus on oak flooring, it takes an oak tree approximately 40 years to reach maturity before foresters can cut it. However, foresters typically harvest them when they reach 60 years.

It’s important to note that several organizations manage tree harvesting. Their focus is on sustaining our forests to avoid deforestation.

Two organizations include the National Wood Flooring Association (NWFA) and the Forest Stewardship Council (FSC). The FSC has a certification process for hardwood flooring manufacturers to ensure products come from responsibly managed forests.

So, the next time you purchase wood flooring, ensure it includes that certification.

Harvesting involves marking the trees and felling them. They then undergo processing, including topping, delimbing, crosscutting into logs, and debarking.

Processing can occur onsite, but it is typically done at a sawmill.

Drying the Harvested Wood

Once at the sawmill, the felled trees are left to dry for three to six months. This process hardens the wood, increasing its durability and quality.

Manufacturers like Bruce want the wood to reach 20–25% moisture levels while sitting in the yard.

Once they reach that mark, the trees move to a kiln for 16 days. The kiln removes even more moisture from the trees, reducing levels to approximately 6–9%. The sawmill takes the felled trees and converts them into lumber.

Milling: Where Trees Become Lumber for Manufactured Hardwood

The transformation from raw lumber to a refined plank demands precision and expertise. Milling is where the timber begins to take shape. The mill first transforms the wood into lumber.

That generally involves rough-cutting timber into thick planks in varying sizes. Typically, they’re 3/4 inch thick and at least 3 inches wide. The width cuts are wider if the production goal is wide plank flooring.

Plank lengths range from six inches to 20 feet.

With solid oak floors, factories use plain sawing, an efficient, lower-cost technique that produces minimal waste and gives the boards a varied grain pattern.

During the process, Bruce, for example, conducts an optimization analysis. Its goal is to achieve the most effective and efficient use of each piece.

Shaping the Wood Flooring Product

Planks are further refined, shaping into the form you see in your home. Planing the wood creates a uniform thickness and smooth surface. It also reveals the wood’s unique grain patterns.

At the same time, knot saws remove defects from each board. Although the process involves scanning equipment, employees also look for imperfections. The goal is to remove any burls, knots, splits, or splintered grain, as they’ll impact the flooring’s grade.

Any trimmed pieces are converted to sawdust, which helps fuel the manufacturing plant. Otherwise, Bruce sells them as components for other wood products.

The quest always focuses on sustainability and efficiency.

Side and End Matching

With side matching, production workers mill a tongue into one edge of the plank. The other edge gets a groove. Both sides receive a bevel on their tops.

Tongue and groove formation enables the planks to fit together seamlessly, ensuring stability and a uniform appearance.

Finally, workers align the plank ends with an end-matching machine to ensure squareness.

Grading the Wood’s Quality

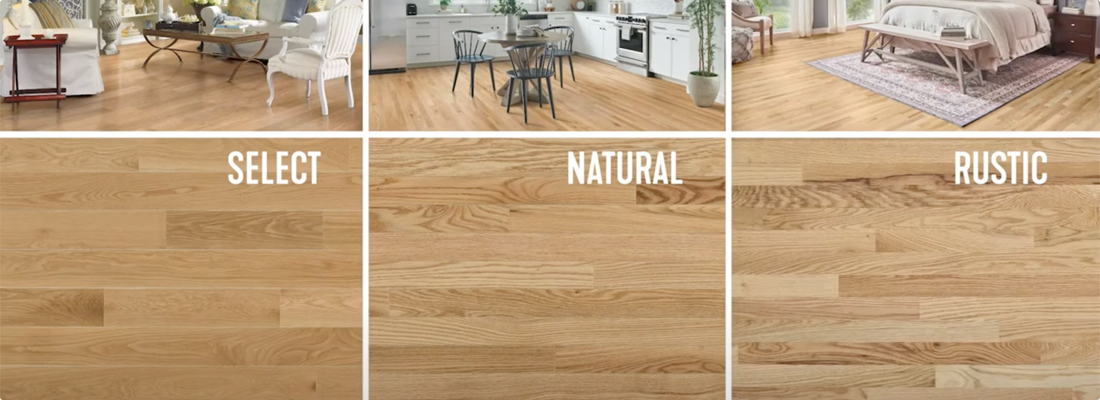

Once the product assumes the appearance of natural hardwood flooring, grading begins. Workers sort the planks for color, clarity, and character. That results in three wood grades:

- Select: This grade has few knots and imperfections. It has a uniform color and grain pattern.

- Natural: The wood has a more varied appearance, including knots, streaks, and color variations.

- Rustic: Rustic grade has the most character, with knots and minor defects that add to its appeal.

During the grading process, workers sort the planks into dark and light. Darker planks receive darker stains, while lighter planks have light stains to show the grain more.

With grading complete, planks move to stacks for final finishing.

Feature Creation During Manufacturing

Many homeowners like wood flooring with wire brushing, hand scraping, embossing, and color washing. That happens as part of the feature creation process. It replicates unique textures to give solid hardwood a time-worn appeal. Much of the process is automated.

Finishing: The Final Step in Hardwood Flooring Manufacturing

The culmination of the hardwood flooring manufacturing process is all about protection and aesthetics. Planks pass through a rapid finishing line where equipment sands and stains them.

Highly trained equipment operators adjust stain colors to maintain consistency and standards.

All processes become part of the plants’ standard operating procedure. The goal is to make all steps repeatable, thereby maintaining consistency and quality standards. As a result, operators receive ongoing training to hone their skills to meet that challenge.

Finally, a protective sealant shields the wood from moisture and enhances the wood’s beauty. For example, Bruce typically uses a durable Dura-Luster® polyurethane finish for solid hardwood flooring. That finish creates a hard surface to protect the wood and ensure years of performance in your home.

Grading the Completed Flooring

The flooring also undergoes rigorous quality checks. Workers grade and sort the finished product, then package it for delivery. Packaging planks from a single production run ensures more consistency in color and character.

America is Built on Bruce® Floors

Bruce has been crafting solid hardwood flooring in the U.S. for over 100 years. It offers solid hardwood in over 200 styles, including the most popular species.

You can also select from various widths in low, medium, and high-gloss finishes.

Find the closest Bruce dealer using our retail locator.