The Best Engineered Wood Flooring for Basements

December 14, 2024 | By Bruce Product Expert

Basements are popular spaces for home improvement, but they’re often one of the trickiest spaces to manage—especially regarding flooring. With moisture, humidity, and temperature fluctuations, not all flooring options can handle this below-ground level.

Enter engineered hardwood: a beautiful, durable, and practical solution that meets the challenges basements present.

Engineered hardwood has quickly become one of the top choices for homeowners. It adds the warmth and charm of wood flooring even in moisture-prone areas like basements. Unlike traditional solid hardwood, engineered hardwood has multiple layers that offer enhanced stability and moisture resistance.

5 Reasons Engineered Hardwood is Ideal Flooring for Basements

Engineered hardwood flooring stands out as the superior choice for basement remodels. Here’s why:

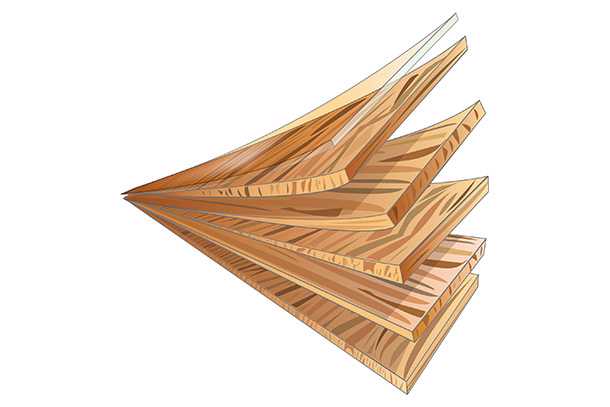

1. Multi-Layer Construction for Stability

Mills create solid hardwood flooring from a single piece of wood. However, engineered hardwood bonds multiple layers of wood or plywood, topped with a layer of natural hardwood veneer. This layered construction makes engineered wood flooring much more dimensionally stable.

As a result, it can withstand moisture and humidity fluctuations without warping or swelling. That gives it a critical advantage for basement installations, where moisture levels change frequently.

2. Moisture Resistance

Basements are notorious for moisture, whether from the ground below or the humidity in the air. Engineered hardwood handles these conditions. Its layered structure allows it to expand and contract less than solid hardwood, reducing the risk of damage from moisture.

You must be aware that engineered hardwoods aren’t 100% waterproof. However, many engineered hardwood products come with finishes or protective coatings that help create an additional barrier against moisture.

For example, Bruce® Hydropel® is a game-changer for moisture-prone areas like basements. Thanks to a watertight locking system, it delivers waterproof hardwood flooring. It also includes a proprietary coating that protects against spills, moisture, and standing water for up to 36 hours.

Its six-layer construction and strong wear layer provide the best of both worlds. You can enjoy the beauty of genuine hardwood and superior water resistance.

With Hydropel, you can even put wood floors in a bathroom.

3. Engineered Wood Has Better Installation Options Over Concrete Subfloors

Most basements have a concrete slab, which can challenge flooring.

Solid hardwood typically requires a plywood subfloor, whereas engineered hardwood can be installed directly over concrete. Many engineered hardwood floors use a floating installation method.

That means the planks snap together and “float” over the subfloor without being nailed or glued down. This method allows for easier and more flexible installation in basements.

4. Aesthetic Appeal Without Compromise

While engineered hardwood has practical benefits, it doesn’t compromise on style. It provides the same timeless beauty and natural wood grain patterns as solid hardwood. You can get the rich, authentic look of wood in your basement. You won’t have to worry about moisture affecting solid hardwood.

Also, engineered floors use real hardwood, unlike wood-look flooring materials like luxury vinyl planks, tile floors, or laminate floors.

5. Cost-Effectiveness

Engineered hardwood is often more cost-effective than solid hardwood. Typically, it costs less than a solid hardwood floor of the same species. Engineered hardwood gives homeowners a stylish and affordable option for upgrading basement flooring. It looks high-end without costing too much.

Compared to hardwood, engineered wood flooring is best for the basement. It delivers moisture resistance, dimensional stability, and ease of installation.

Key Features to Look for in Engineered Hardwood for Basements

Not all engineered hardwood products are created equal, especially when choosing flooring for a basement. Certain features are essential to maximize durability, comfort, and long-term performance.

Here are the key factors to keep in mind when selecting the right engineered hardwood for your basement renovation:

Thicker Engineered Hardwoods Resist Warping

The thickness of engineered hardwood is one of the most essential aspects. Typically, engineered hardwood comes in various thicknesses, the most common being between 3/8 inch and 3/4 inch. For basement installations, thicker boards offer greater stability and durability, especially in high-traffic areas.

In addition to overall thickness, the number of layers that make up the plank is crucial. More layers generally mean increased dimensional stability. That helps the floor resist warping or buckling from temperature or moisture changes. Look for engineered hardwood with at least 5 to 7 layers for optimal performance in basement environments.

Look for a Waterproof Engineered Hardwood

Since basements are prone to higher moisture levels, choosing an engineered hardwood floor with enhanced moisture resistance is vital. As mentioned, some engineered flooring, like Hydropel, comes with a protective finish to help create a barrier against moisture. These features are significant in basements where unexpected leaks or excess humidity could damage the floor.

In addition to the floor itself, consider installing a moisture barrier or underlayment designed to handle moisture and humidity. It provides an extra layer of protection between the concrete flooring, ensuring your basement stays dry and comfortable.

Choose an Engineered Floor with a Thick Wear Layer

Engineered hardwood’s durability largely depends on the thickness of its wear layer—the top layer of real hardwood. For basement installations, you’ll want a wear layer that can withstand foot traffic, furniture, and general wear and tear.

Equally important, with thicker wear layers, you can sand and refinish your floors, prolonging their life.

Select a Durable Wood Species

Choosing the right wood species for your engineered hardwood floor can also impact its performance in a basement. Some species naturally handle moisture better than others.

For instance, oak and hickory are excellent choices for basements owing to their hardness. Their density helps resist swelling and shrinking. Conversely, lighter woods like pine may be more susceptible to moisture-related damage.

Use an Underlayment with Engineered Hardwood in Basements

An underlayment can significantly improve the performance of engineered hardwood floors in a basement. A high-quality underlayment provides additional moisture protection, adds insulation, reduces noise, and improves the comfort of the floor and living space.

5 Installation Tips Engineered Hardwood in Basements

Proper installation is crucial to ensuring the longevity and performance of engineered hardwood flooring in your finished basement. Here are some essential tips to follow to get the best results:

1. Prepare the Subfloor

Since most basements have concrete subfloors, preparing the surface is the first step. Ensure that the subfloor is level, clean, and dry before installation. Uneven or damp subfloors can lead to issues like warping, buckling, or uneven wear over time.

Conduct a moisture test using a moisture meter to avoid moisture seeping through the concrete. If moisture levels are too high, consider using a moisture barrier or sealant.

2. Choose the Right Underlayment

An underlayment provides additional protection against moisture while offering noise reduction and added comfort underfoot. Choose an underlayment specifically designed to handle moisture, such as a vapor barrier underlayment. The underlayment is an extra shield between the subfloor and your engineered hardwood, preventing moisture-related damage.

3. Use the Floating Installation Method

A floating floor is typically the easiest and most effective for basement installations. With this method, the engineered hardwood planks snap together and “float” over the subfloor without needing adhesives or nails.

This method is especially beneficial in basements. It allows the floor to expand and contract with changes in humidity and temperature without becoming water-damaged. It also allows for easier installation over a moisture barrier, protecting the floor from basement dampness.

4. Allow for Expansion Gaps

Even engineered hardwood can expand and contract in response to changes in humidity. So, leave expansion gaps between the flooring and the walls. These gaps allow the floor to move slightly without buckling or warping.

Typically, a gap of around 1/4 inch will suffice. You can hide the gap with baseboards or trim.

5. Acclimate the Flooring

Before installation, it’s essential to allow the engineered hardwood to acclimate to the basement environment. Store the flooring planks in the basement for at least 48 hours before installation. This allows them to adjust to the space’s temperature and humidity, helping reduce expansion or contraction issues post-installation.

Bruce® Has the Best Engineered Wood Flooring for Basements

Engineered hardwood is an ideal choice for basement flooring. It offers the warmth and beauty of wood while combining durability and moisture resistance to address below-grade spaces.

Bruce Flooring offers engineered hardwood products perfect for any basement project. You can choose from more than 150 different selections. Plus, options like Hydropel waterproof engineered hardwood come with a lifetime warranty.

You can shop for Bruce hardwood and engineered hardwood at flooring retailers near you.

Ready to shop for engineered hardwood flooring for your basement?

Use our retail locator to find where you can buy Bruce engineered hardwoods.

Find a Store

Solid vs Engineered Hardwood Flooring

Solid vs Engineered Hardwood Flooring Guide To Choosing a Hardwood Floor

Guide To Choosing a Hardwood Floor Hardwood Flooring Room Inspiration Guide

Hardwood Flooring Room Inspiration Guide 10 Things to Know About Hardwood Floor Installation

10 Things to Know About Hardwood Floor Installation How To Clean and Protect Hardwood Flooring

How To Clean and Protect Hardwood Flooring